Click here to download a PDF version of this Cultivation Insights article.

» Increasing the electrical conductivity (EC) of nutrient solutions can help increase the concentration of soluble solids and acidity

levels in greenhouse-grown tomato fruit.

» Increased salinity levels and reduced irrigation rates can have similar effects on fruit composition and flavor.

» Increasing EC, salinity, or lowering irrigation rates can also reduce plant growth and fruit yields.

Protected culture tomato production systems allow growers to manage environmental conditions such as temperature, humidity, and CO2 levels, as well as provide even moisture levels and balanced nutrient solutions. This level of control helps to allow for higher yield potentials than are typical for open-field production systems.1 However, the focus of greenhouse tomato production has gradually changed from the quantity to the quality of fruit production, particularly the flavor of tomato fruits.2 Tomato flavor is determined by a number of factors, including the amount of sugars, acids, and various volatile compounds present in the fruit at the time of consumption. Increasing the amount of sugar and acid in the fruit can have a big impact on fruit flavor and perceptions of fruit quality.1,3 The best tomato flavor is usually associated with high soluble solid levels and the ratio of soluble solids to titratable acidity (high sugar and acid levels).4

Figure 1. Greenhouse tomatoes allowed to ripen on the vine.

Figure 1. Greenhouse tomatoes allowed to ripen on the vine.

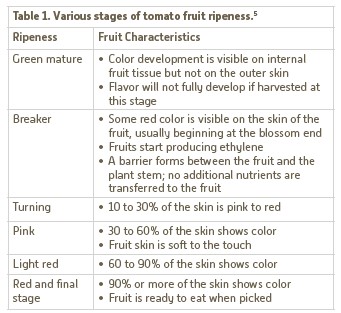

Tomato flavor is affected by genetics (tomato variety), and varieties do have distinct flavor profiles. However, external factors can also affect the flavor of the fruit. One reason that greenhouse-grown tomatoes may develop better flavor than commercial, field-grown tomatoes available in grocery stores is the level of fruit ripeness at the time of harvest (Figure 1). There are six stages of ripeness for tomato fruits (Table 1). Many commercial, field-grown tomatoes are harvested at the

green-mature stage before the flavor is fully developed.5 Most greenhouse grown tomatoes are harvested at the breaker stage or later, after the fruits have received all of the nutrients that they will receive from the plant. This is considered the “vineripe” stage, and the fruits have developed the vine-ripe flavor.3,5 Post harvest handling and storage should be at temperatures between 50° and 55°F (10° and 13°C). Lower temperatures can delay time to the table-ripe stage, while higher temperatures can hasten the degradation of fruit quality.3

EFFECT OF EC LEVELS ON FLAVOR

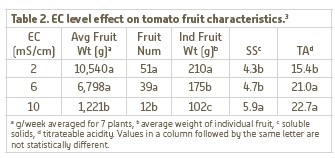

Research has shown that EC levels of hydroponic nutrient solutions are closely associated with the composition and quality of tomato fruit.2 EC levels near 2 dS/m are often recommended for solutions used for greenhouse-grown tomatoes at the fruit set and development phases to help maximize yield potential.2 Levels much lower than this can result in the development of nutrient deficiency symptoms, reduced plant growth, and lower fruit yield and quality. Higher levels of blossom end rot were also seen in treatments with higher EC levels.

Studies conducted in Isreal and the U.S. on the effects of growing tomatoes in saline soils or irrigating with brackish water have found that tomato plants exposed to higher salinity conditions did show reductions in fruit yield, but the fruits produced on those plants tended to have higher concentrations of sugars and acids. Some evaluations of taste noted that tomato fruit produced in saline conditions tasted better with fewer off-flavors compared to tomatoes grown in lower salinity conditions.6,7 A study evaluating the effect of irrigating soil-grown tomatoes with salty water (4 dS/m) had fruit yields 17% lower than tomatoes irrigated with fresh water (1.6 dS/m), but that the fruit from the salty treatment had significantly higher levels of total soluble solids (5.8% vs. 5.3%), increased fruit acidity (0.6% vs 0.5%) , and higher levels of vitamin C (27 vs 23 mg/100g fresh weight).6 Another study looking at the effects of irrigating with brackish water and amending soils with SEA-90, a source of sodium and other minerals, also found that the elevated sodium levels were associated with increased acidity, sugar content, soluble solids, and improved flavor of fruit. It also noted that the fruit from the salt-treated plants ripened faster.7

Studies of protected culture systems have evaluated the effects of nutrient solution EC levels on fruit yield and quality of hydroponically grown tomatoes.2,3,8,9 Increasing the EC of the solution can result in increased accumulation of soluble solids, starch, organic acids, and amino acids in the fruit. However, increasing EC can result in negative effects such as reduced plant growth, photosynthesis, and fruit weight (Table 2).2,3

The EC of the solution can be increased by adding higher levels of various nutrient salts or by adding other salts, such as NaCl.7,8 Increasing the salinity (adding NaCl) can result in increased levels of sugar, organic acids, and other compounds in the fruit.2 However, increased NaCl levels often reduce fruit yield more than increasing nutrient concentrations. One study showed that at the same elevated EC level, treatments using NaCl to increase EC had 10% less fruit yield when compared to treatments where the EC was elevated with increased nutrient concentrations.8

EFFECT OF IRRIGATION LEVELS

Increasing the EC of a nutrient solution or salinity of a soil makes it more difficult for plant roots to extract water from the soil or container medium. Reduced water availability in the plant lowers the amount of water going into the fruit, thus lowering fruit weight but increasing the concentrations of sugars and acids. Studies evaluated whether similar results could be attained by reducing the amount of available water by adjusting irrigation rates. As seen with increased EC/salinity levels, reducing the amount of water through irrigation rates did result in increased levels of sugars and acids in the fruit, but also lower fruit weights, reduced numbers of marketable fruit, inhibited plant growth, and higher rates of blossom end rot.2,7 Too little water can result in reduced fruit set as well.

Improving tomato flavor using these methods in a commercially feasible way will require attaining an appropriate balance of flavor, yield potential, and fruit disorders. Some tomato types may be better suited to these methods. Fruit size of cherry tomatoes may not be as important to the consumer as flavor.

EFFECTS OF ROOT STOCKS

Tomatoes are grafted onto rootstocks to help increase growth, tolerate saline conditions, and manage soilborne diseases. Grafting onto rootstocks may also positively or negatively affect fruit flavor. It has been shown that rootstock grafting can result in changes in soluble solids (sugar) levels in the fruit. Sometimes these changes result in more flavorful fruit, but other times the fruit may exhibit off-flavors. 10,11 Different rootstock/scion combinations can result in different effects on flavor. Growers should be aware that different scion/rootstock combinations can result in different effects (positive and negative) on fruit flavor.

SOURCES

12025. How greenhouse growing enhances the flavor and quality of tomatoes. Greenhous Goodness. https://greenhousegoodness.com/blog/how-greenhouse-growing-enhances-theflavor-and-quality-of-tomatoes/.

2Ou, X., Liu, D., Liu, A., Liu, H., Chen, R., and Zhang, Y. 2023. Effects of nutrient solution management modes on fruit production and quality of tomatoes grown in extremely root restriction. Scientia Horticulturae 321: 112366. https://doi.org/10.1016/j.scienta.2023.112366.

3Lin, W. and Block, G. 1998. The effects of culture practice and storage temperature on quality and flavor volatiles of greenhouse tomatoes. Acta Hortic. 464:213-218. https://doi.org/10.17660/ActaHortic.1998.464.30.

4Mikkelsen, R. 2005. Tomato flavor and plant nutrition: A brief review. Better Crops 89:14-15.

5Diffenderfer, D. 2024. Is this tomato ready to harvest? PennState Extension. https://extension.psu.edu/is-this-tomato-ready-to-harvest.

6Glion, H., Alkalai-Tuvia, S., Zaaroor-Presman, M., Chalupowicz, D., Zanbar, M., Amichai, M., Cohen, S., Shemer, T., Sarig, S., and Fallik, E. 2019. Effects of rootstock/scion combination and two irrigation water qualities on cherry tomato yield and postharvest fruit quality. Horticulturae 5:35. doi:10.3390/horticulturae5020035.

7Byczynski, L. 2010. New strategies for great-tasting tomatoes. Growing For Market. https://growingformarket.com/articles/Improve-tomato-flavor.

8Li, Y., Stanghellini, C., and Challa, H. 2001. Effect of electrical conductivity and transpiration on production of greenhouse tomato (Lycopersicon esculentum L.). Sci. Hort. 88:11-29. https://doi.org/10.1016/S0304-4238(00)00190-4.

9Peet, M. 2004. Fruit quality and yield in five small-fruited greenhouse tomato cultivars under high fertilization regime. In Cantliffe, D., Stoffella, P., and Shaw, N. (eds.) Proc. VII IS on Prot. Cult. Mild Winter Climates, Acta Hort. 659, ISHS.

10Zhou, Z., Yuan, Y., Wang, K., Wang, H., Huang, J.,Yu, H., and Cui, X. 2022. Rootstock-scion interactions affect fruit flavor in grafted tomato. Horticultural Plant Journal 8(4):499-510.

11Jenkins, T., Cowan, J., Rivard, C. L., and Pliakoni, E. 2022. Effect of rootstock on ‘Tasti-Lee’ tomato yield and fruit quality in a high tunnel production system. HortScience, 57(10):1235-1241.

Websites verified 7/7/2025

ADDITIONAL INFORMATION

For additional agronomic information, please contact your local seed representative.CPerformance may vary, from location to location and from year to year, as local growing,Csoil and weather conditions may vary. Growers should evaluate data from multiple locationsCand years whenever possible and should consider the impacts of these conditions on theirCgrowing environment. The recommendations in this article are based upon information Cobtained from the cited sources and should be used as a quick reference for information about greenhouse cucumber production. The content of this article should not be substituted for the professional opinion of a producer, grower, agronomist, pathologist and similar professional dealing with this specific crop.

BAYER GROUP DOES NOT WARRANT THE ACCURACY OF ANY INFORMATION OR TECHNICAL ADVICE PROVIDED HEREIN AND DISCLAIMS ALL LIABILITY FOR ANY CLAIM INVOLVING SUCH INFORMATION OR ADVICE.

6810_592500 Published 07-7-2025