Click here to download a PDF version of this spotlight.

» Seed treatments and enhancements can improve stand establishment, survival, and quality and appearance of onions.

» Seed enhancements include seed priming and seed coating procedures.

» Seed treatment insecticides and fungicides can protect yield potential from losses to onion pests and diseases.

Onion seed can be treated in several ways prior to planting to improve quality and yield potential. The term “seed treatment” typically refers to the application of insecticides and/or fungicides to the seed to help protect the seeds and young seedlings from insect pests and fungal pathogens. The term “seed enhancement” usually refers to other processes, such as seed coatings or pelleting, seed priming, or post-priming procedures that are intended to improve the handling and planting of seed, reduce the time to germination, or increase the uniformity of seedling emergence.

SEED ENHANCEMENTS

The first step in germination is the imbibition of water by the seed. Imbibition of water starts the physiological processes that allow the seed to break dormancy and germinate. One way to speed the process of germination after planting is to prime the seed before planting. Seed priming is defined as “pretreatment of seeds by various methods to improve seed germination rate, percentage germination, and improve the uniformity of seedling emergence by controlling the water available in the seed.”1 Typically seeds are soaked in a water solution to start the germination process, but then they are dried before they sprout. Once planted, primed seed emerge more quickly and uniformly than non-primed seed. However, priming usually shortens the shelf-life of the seed, so seed should be planted within six to twelve months of priming.

During the priming process, proteins and sugars that protect seed from damage during dormancy are broken down, as they would no longer be needed if the seed were to continue to germinate. When seeds are dried before sprouting, they no longer contain most of these protective proteins and sugars. Post-priming enhancement is a process initiated after priming but before re-drying. It is intended to promote the reforming of these proteins and sugars to help protect the seed after priming.

Because they are fairly small and irregularly shaped, onion seeds can be difficult to plant mechanically. The application of seed coatings can improve handling and planting by making the seed more uniform and spherical. Coatings can also help applied seed treatment products remain on the seed.

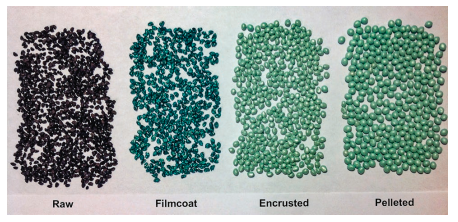

Figure 1. Onion seed with various seed coatings

Figure 1. Onion seed with various seed coatings

There are three basic types of seed coatings (Figure 1). Filmcoats are very thin and do not change the shape, size, or weight of the seed, and they can help reduce water loss.2 Encrustments are somewhat thicker, making the seed more uniform in shape, more spherical, and slightly heavier. Encrusted seed is easier to plant than non-coated seed when using a vacuum seeder. Pelleted seeds have the thickest coatings, are more uniform in size and shape, and are heavier. Pelleted seeds are easier to handle and plant in operations using belt- or vacuum-seeders. Encrustments and pellets have the added advantage of being able to physically separate seed treatment products from the seed. It has been shown that some insecticides can be phytotoxic, and may result in lower viability and germination if applied directly to the seed. The added layer of material between the seed and product can reduce this problem.

SEED TREATMENTS

Seed treatment products are applied to the seed to protect seeds and seedlings from insect pests and seedborne/ soilborne pathogens. Seed treatment products are usually applied at very low rates directly to the seed, and they are typically very cost-effective with minimal environmental impact.

Onions planted in the muck soils of the eastern United States and Canada tend to have more problems with soilborne diseases and insects than do onions planted in the more mineral soils of the western U.S. and Mexico because the conditions for survival and infection are more favorable in the eastern locations. As a result, different seed treatment products are typically used in different planting areas.

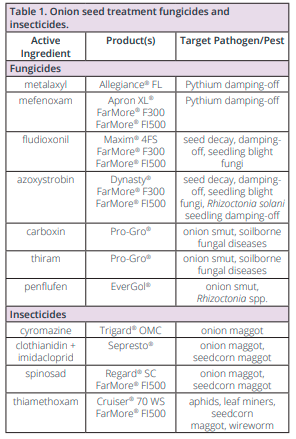

The cool, wet conditions in the eastern U. S. and Canada promote the development of damping-off diseases caused by pathogens such as species of Pythium, Fusarium, and Rhizoctonia. These pathogens reside in the soil and attack seeds and seedlings, both before and after emergence. Seed rots can also result from fungi, such as Aspergillus, Botrytis, and Penicillium species, which are on or in the seed prior to planting, and these fungi colonize and rot the seed when moisture becomes available. Both seed rots and damping-off result in poor stand establishment and reductions in yield. Products containing azoxystrobin, fludioxonil, penflufen, and thiram help control the other seed- and soil-borne fungal pathogens (Table 1).

In the drier growing regions of the western U.S. and Mexico, damping-off and seedling blight caused by the fungus Rhizoctonia solani tend to be the biggest problems, although the seed rot and other damping-off pathogens can cause disease under certain circumstances in these areas as well.3 Seed treatment products containing azoxystrobin and penflufen can help control diseases caused by Rhizoctonia secies.

Onion smut is another disease caused by a soilborne fungus. Spores of the fungus infect the leaves of onion seedlings shortly after emergence, and seedlings can be killed within three to five weeks. For seedlings that survive, the fungus will progress from the leaves down to the bulbs, causing brown to black lesions.4 Products containing carboxin, thiram, or penflufen are used to help control onion smut.

Onion maggots and seedcorn maggots are both insects that feed on and damage onion plants. The insects overwinter as pupae in the soil. Adults emerge in the spring and lay eggs in the soil near onion plants. Larvae burrow into the basal plate of the plant and begin to feed on bulb tissue. Damaged seedlings wilt and can eventually die. Two or more generations of the onion maggot insect develop during the season. Seed treatments can protect seedlings from feeding by the first generation larvae, and this can reduce the number of subsequent generations that develop in the field.5 Several seed treatment products contain insecticides that help control onion maggots and other insect pests (Table 1).

The availability of seed treatment products for onion vary by country and by state in the U.S. Check local management recommendations and product labels to determine the products that are registered for use in your location.

SOURCES

1 National Agricultural Thesaurus and Glossary. http://agclass.nal.usda.gov/.

2 Taylor, A. G., Hoepting, C. A., Nault, B. A., Lorbeer, J. W., and. McDonald, M. R. 2008. Onion seed treatment and coating technologies. Acta Hortic. 782, 129-134.

3 du Toit. L., Holms, B., Twomey, M., Gatch E. 2008. Evaluation of seed treatments for soilborne damping-off pathogens and seedborne fungi of onion. PDMR 3:ST021.

4 Delahaut, K. and Stenenson, W. 2004. Onion disorder: Smut. A3796. University of Wisconsin Cooperative Extension.

5 Smith, E. and Nault, B. 2014.Onion maggot Delia antique. Cornell University, NYS IPM Fact sheets for vegetables.

6 Hoepting, C, and Nault, B. 2021. New seed treatment options for onion maggot: What growers need to know. Cornell Cooperative Extension.

Web sources verified 12/01/2021

ADDITIONAL INFORMATION

For additional agronomic information, please contact your local seed representative.

Performance may vary from location to location and from year to year, as local growing, soil and weather conditions may vary. Growers should evaluate data from multiple locations and years whenever possible and should consider the impacts of these conditions on the grower’s fields. The recommendations in this article are based upon information obtained from the cited sources and should be used as a quick reference for information about onion production. The content of this article should not be substituted for the professional opinion of a producer, grower, agronomist, pathologist and similar professional dealing with this specific crop.

BAYER GROUP DOES NOT WARRANT THE ACCURACY OF ANY INFORMATION OR TECHNICAL ADVICE PROVIDED HEREIN AND DISCLAIMS ALL LIABILITY FOR ANY CLAIM INVOLVING SUCH INFORMATION OR ADVICE.

2061_SE_S1 Published 01-05-2022

FarMore® Technology is an on-seed application of separately registered seed protection products and proprietary application technologies. FarMore F300 contains three fungicides: Apron XL®, Maxim® 4FS and Dynasty®. FarMore FI500 contains three fungicides: Apron XL®, Maxim® 4FS and Dynasty®; and two insecticides: Regard™ and Cruiser® 70WS. ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Not all products are registered in all states and may be subject to use restrictions. The distribution, sale, or use of an unregistered pesticide is a violation of federal and/or state law and is strictly prohibited. Check with your local dealer or representative for the product registration status in your state. Apron XL®, Cruiser®, Dynasty®, FarMore®, Maxim®, Regard™ and Trigard® are trademarks of Syngenta Group Company. Allegiance®, Bayer, Bayer Cross, EverGol® and Seminis® are registered trademarks of Bayer Group. All other trademarks are the property of their respective owners. For additional product information call toll-free 1-866-99-BAYER (1-866-992-2937) or visit our website at www.BayerCropScience.us. Bayer CropScience LP, 800 North Lindbergh Boulevard, St. Louis, MO 63167. Bayer CropScience Inc. is a member of CropLife Canada. ©2022 Bayer Group. All rights reserved.